Featured Projects Utilizing ArcelorMittal Structural Steel

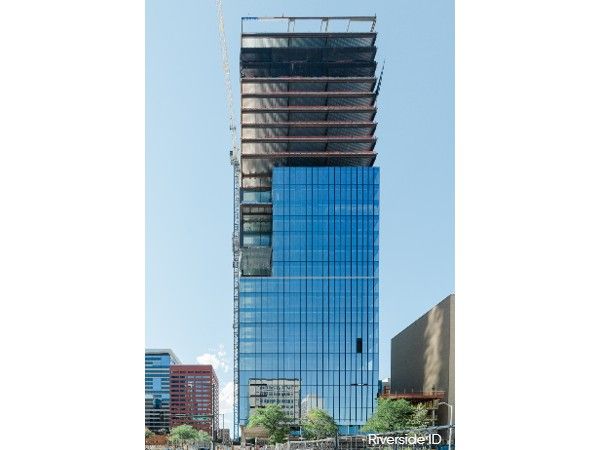

Owner/Developer: Canyon Partners Real Estate LLC; Convexity Properties; Riverside Investment & Development

Architect: Goettsch Partners

Engineer: Magnusson Klemencic Associates

General Contractor: Hensel Phelps

Fabricator: Puma Steel

1900 Lawrence is a 30 story, 1.1 million square foot office building in Denver, Colorado. ArcelorMittal provided A913 Gr. 80 for column sections ranging in size from W14x159 to W14x665. In addition, W14x500 A913 Gr. 80 sections were provided for the diagonal members of the transfer truss. Utilizing A913 reduced overall column weight by 275 tons.

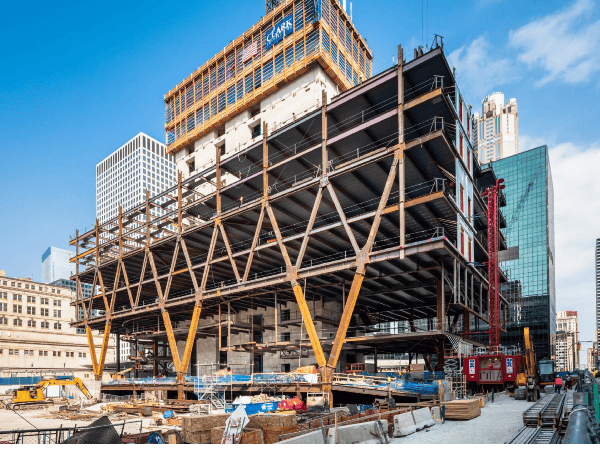

Owner/Developer: Riverside Investment & Development

Architect: Goettsch Partners

Engineer: Magnusson Klemencic Associates

General Contractor: Clark Construction Group

Fabricator: Zalk Josephs

BMO Tower, a 50-story office building in Chicago, Illinois, stands out as the first structure in the US to adopt ArcelorMittal A913 Gr. 80 steel, contributing to a 275 ton decrease in the weight of its steel columns. To ensure that A913 Grade 80 was the most cost-effective solution, structural engineer Magnusson Klemencic and Associates implemented a triple column schedule, designing the gravity columns in multiple grades of A913 steel and letting the market determine the most economical option.

Read more about BMO Tower from the structural engineer, MKA

Read more about BMO Tower from developer, Riverside Investment and Development

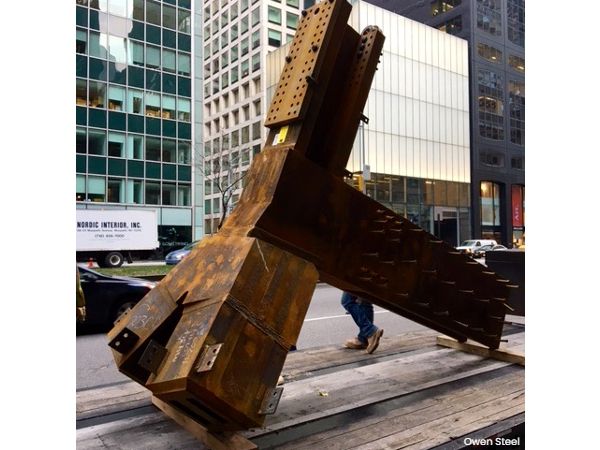

Owner/Developer: L&L Holding Company, LLC

Architect: Foster + Partners

Engineer: WSP

General Contractor: AECOM Tishman

Fabricator: Owen Steel

Located in New York, NY, 425 Park Avenue is an 815 foot, 42 story office building. This project utilized jumbo W14x873 steel sections, exclusively rolled by ArcelorMittal. Further, columns throughout the structure incorporated ArcelorMittal A913 Gr. 70 steel, contributing to a noteworthy 30% reduction in weight.

Owner/Developer: Brookfield Properties

Architect: Adamson Associates; KPMB Architects

Engineer: Entuitive

General Contractor: Multiplex Construction Canada

Fabricator: Walters Group

Bay Adelaide North is a 32-story office building and the final installment of a trio of towers in Toronto, Ontario. Although each of the three towers utilized A913 high-strength steel, Bay Adelaide North distinguished itself by pushing boundaries through the adoption of A913 Gr. 80. The collaborative efforts of the fabricator and design team, working in tandem with ArcelorMittal's technical and research and development teams, ensured the seamless integration of this innovative material.

Owner/Developer: Ivanhoé Cambridge; Société immobilière Trans-Québec; Hines Canada Management Co. ULC

Architect: Adamson Associates; WilkinsonEyre

Engineer: RJC Engineers

General Contractor: EllisDon Construction Services

Fabricator: Walters Group; Supermetal

Located in Toronto, Ontario, the two office buildings at 81 and 141 Bay Street stand tall at 49 and 50 stories, respectively. 81 Bay Street was the first tower constructed and incorporated nearly 3000 tons of ArcelorMittal A913 Gr. 65 steel. 141 Bay Street, the second tower, harnessed a newer technology, utilizing over 1000 tons of ArcelorMittal A913 Gr. 80 steel as well as Gr. 65 and 70.

Owner/Developer: Cadillac Fairview Corporation Ltd

Architect: Adrian Smith + Gordon Gill Architecture

Engineer: RJC Engineers

General Contractor: PCL Constructors Inc.

Fabricator: Walters Group

At 46 stories, 160 Front Street West will stand out on Toronto’s skyline for years to come. The design team incorporated over 3600 tons of ArcelorMittal A913 Gr. 70 sections, providing much-welcome weight savings on a project with over 12000 tons of structural steel.

Owner/Developer: Riverside Investment & Development

Architect: Goettsch Partners

Engineer: Magnusson Klemencic Associates

General Contractor: Clark Construction Group

Fabricator: Zalk Josephs

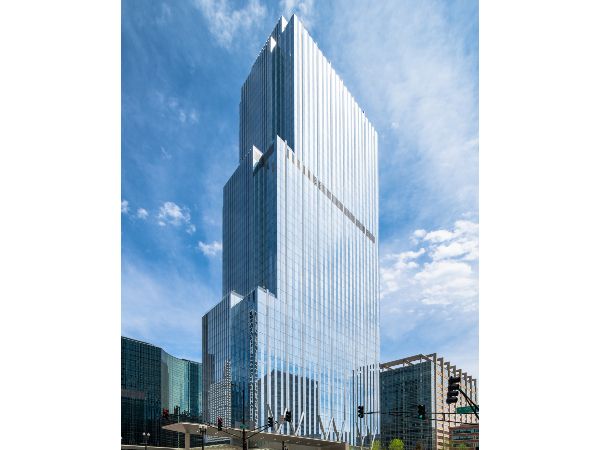

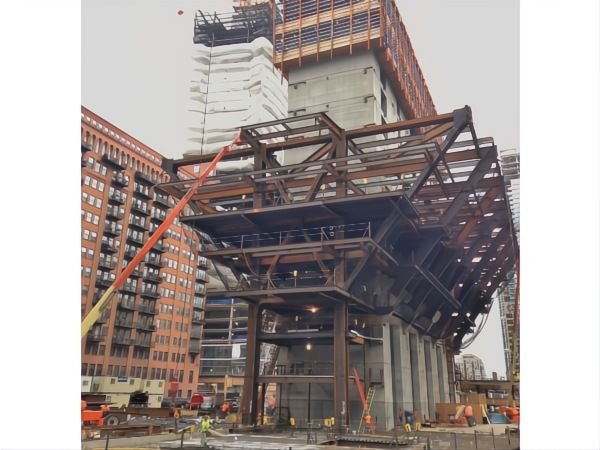

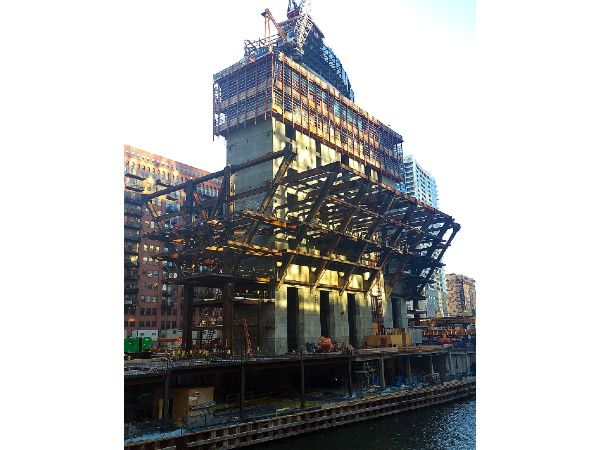

At 54 stories and 747 feet tall, 150 North Riverside is a staple on the Chicago River and a must-stop attraction for all Chicago Architecture tours. The building is designed by the architectural firm Goettsch Partners, with Magnusson Klemencic Associates serving as structural engineer of record. The signature component of 150 N Riverside is the way the building appears to stand on one foot. With its vertical exterior columns seemingly terminating at level 8, the building has a significantly smaller base when compared to the typical floors above.

This special layout was required to accommodate the complexities of the building site. The project is located just a few feet away from the Chicago River at its east and a rail yard that has been active for more than a century at its west. The constraint of the railway, which made it impossible for the building’s exterior columns to extend to solid ground, pushed the design team to develop what is known as a core-supported framing plan.

In the core-supported plan, the building was essentially designed as a typical office building from level 8 through level 54 with an efficient, yet complex, transfer truss system that enables the weight of the building to be supported on its concrete core below level 8.

The structural engineer, in cooperation with Zalk Josephs, the project’s fabricator, determined that incorporating 70 ksi steel sections into the design would lead to considerable savings in weight, fabrication hours and cost. Prior to the material being specified on this project, A913 Grade 70 rolled shapes had been used on only two projects (both in Canada), so 150 N Riverside became the world’s third project and the first in the United States to feature 70 ksi rolled shapes.

ArcelorMittal provided the fabricator with steel sections in A913 Grades 65 and 70, including the W36x925 and W14x873 sections - some of the largest shapes in the world and uniquely produced at ArcelorMittal’s Differdange mill.

Overall, ArcelorMittal’s products offered the most cost-effective approach to designing the structural system for this distinctive building. Our large sections and high strength material provided the only “off-the-shelf” solutions that could resist the building’s heavy loads. A list of specific benefits ̶ identified by the customer ̶ that ArcelorMittal’s steel brought to this project follow:

- Incorporation of A913 Grade 70 material into the perimeter columns enabled the use of 65 ksi rolled shapes at the base of the structure. This resulted in significant savings in fabrication and erection costs and a total tonnage reduction of 550 tonnes. Overall, for 150 N Riverside the total savings in the weight of the structural frame was 6%. When comparing the savings to the columns, where the high-yield A913 steels were most commonly employed, the weight savings was 18%.

- In addition to the weight savings, the fabricator noted benefits from the avoidance of preheat requirements when welding A913 Grade 65 material. In particular, 150 N Riverside features cantilevered framing elements composed of thick sections for which it was necessary to connect by welding completely across their cross sections (this is known as a Complete Joint Penetration (CJP) weld). ASTM A913 Grade 65 steel is approved by the American Welding Society to be connected characteristic is unique to this grade, and the major benefit of it is that the fabricators can save a lot of time and energy in their processes.

- Lastly, the use of the high strength steel and larger section sizes eliminated virtually all cover plating requirements for the columns. Again, a major benefit to the fabrication of the project, removing the need to cover plate columns saves a significant amount of labor hours and cost on projects.

Read more about 150 N Riverside in Modern Steel Construction

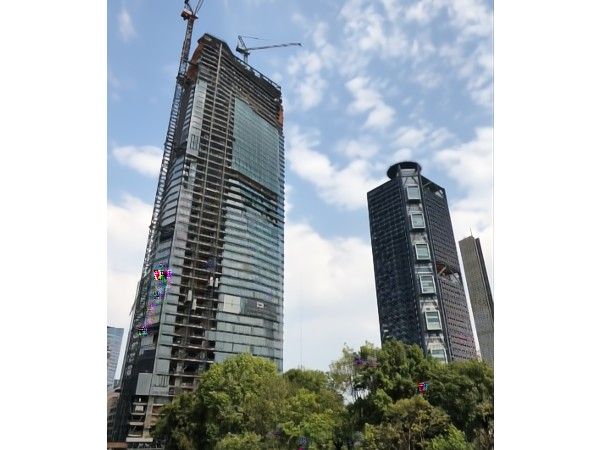

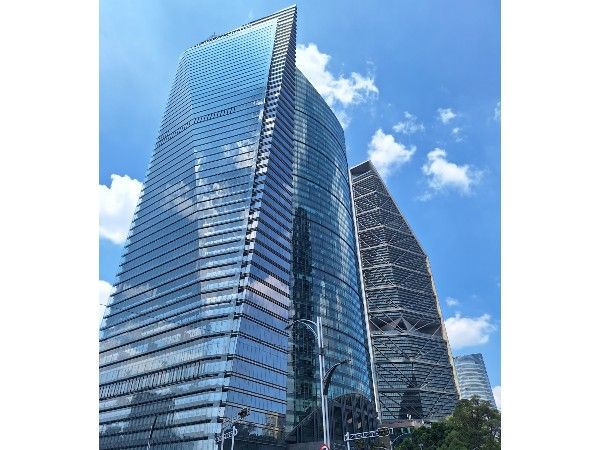

The beauty of modern architecture is shown through towers Chapultepec I, Mayor and Reforma in Mexico City. These projects utilized over 15,000 tons of structural sections, while A913 Gr. 65 helped engineers to optimize the columns of these iconic buildings.

Home

Home